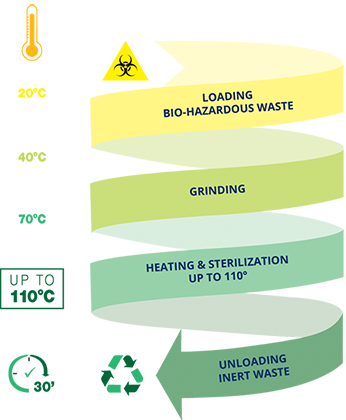

As it uses the microwave technology, Sterilwave is the easiest, most efficient and economical solution to manage medical waste onsite.

| Waste management method | No specific construction required |

No polluting emissions |

|||||

|---|---|---|---|---|---|---|---|

| Dry | Stable | Sterilized | |||||

| STERILWAVE | |||||||

| Autoclave | Some models | Some models | |||||

| Incineration | |||||||

| Chemical treatment | Some models | Some models | |||||