200L/h

Up to 20 kg/h

(with a density of 1L = 0,1kg)

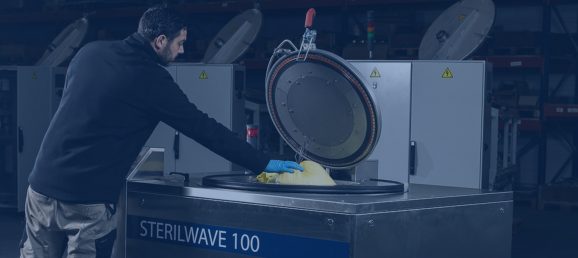

Sterilwave 100

The Sterilwave 100 is particularly suited to medical facilities generating only small amounts of waste. This biomedical waste management system can treat up to 20kg of waste per hour*. Sterilwave 100 is ultra-compact and comes in a mobile version, for use in a container for example.

The Sterilwave 100 was approved by the French Ministry of Health in 2017 and complies with the strictest environmental and bacteriological reduction standards. It allows small institutions (e.g. laboratories, small clinics and hospitals) to carry out safe, on-site treatment of up to 200L of biomedical waste per hour (20kg/hr*).

Its innovative concept uses a suspended vessel and rotating grinder blades to grind down all types of waste, including metallic objects. Biohazardous waste is sterilised using microwaves and converted into inert municipal waste, reducing its volume by more than 80% and its weight by 25%. Its environmental impact and operating costs are reduced while ensuring the safety of the operator. As it uses microwave technology, the Sterilwave does not need a steam generator, so there is no risk from excess pressure and no liquid effluent is produced. Its ultra-compact size means its installation only requires 10m² of space. The Sterilwave 100 is the solution for easy use and maintenance, with operating costs which are amongst the lowest on the market.

(* with a density of 0.1kg/L)

Reasons to choose Sterilwave 100

Effective

Bacterial inactivation higher than international regulatory standards (up to 8log10)

Plug & Play

Ready-to-use system which requires no specific technical qualifications

Environmentally-friendly

No environmental impact – On-site treatment – No transportation – No liquid effluent.

Safe

Technology combining shredding & microwave sterilization in one single vessel – No pressurisation unlike in an autoclave.

Economical

Robust equipment – Quick return on investment – No more storage, easy to maintain – Most competitive operating cost on the market.

Waste capacity

Vessel capacity

100 L

Average cycle time

30′

Dimensions (L x W x D)

1,7 x 1,2 x 1,1 m

Weight

700 kg

Working area

10 sq.m

Ceiling height: 2m

Electricity

400V/ 3-Phase, 40A

Technology

Grinding by rotating blades and heating by microwaves

Microbial inactivation

Spore up to 8log10

Virus up to 6log10

STAATT requirements and NFX30-503 compliant

Volume reduction

Up to 85%

Weight reduction

Up to 25%

Final Waste

Unrecognizable, inert, dry, stable

Loading Process

Manual

Process management

Full traceability

Full decontamination

Biohazardous waste is sterilised with microwaves (heat it up to 110°C for 20 minutes) and allows microbial inactivation of up to 8log10.

Safe processing

Microwave sterilisation technology does not require pressurisation, and this removes any risk of explosion. Moreover, the microwaves are confined to the inside of the vessel to avoid operator exposure to radiation.

No liquid effluent

The treatment process does not produce any steam or liquid effluent, which means no consumption of water and no need to include an effluent drainage system in its installation.

No segregation

The Sterilwave is suitable for all types of biomedical waste (needles, glass, solids, liquids, etc.)

Easy maintenance

The equipment is built using robust technology. IP connection for diagnostics. Preventive maintenance plan/calendar with alarm.

Reduces weight by 25% and volume by 85%

Biomedical waste is converted to inert waste similar to municipal waste. The dry ground-up waste can also be used as secondary fuel.

With its automated grinding and microwave sterilisation process contained in a single vessel, the Sterilwave can produce bacterial inactivation (higher than 8log10) of biomedical waste in less than 30 minutes, in complete safety and without intermediate handling. Unlike autoclave technologies, our system does not require the vessel to be pressurised. The Sterilwave converts biomedical waste into dry waste which is inert and completely disinfected, reducing its weight by more than 25% and its volume by 85%. The end product is similar to municipal waste and can then be fed into standard urban waste systems.

ANY QUESTIONS? CONTACT AN EXPERT

Please fill in this form if you wish to contact our sales team or receive further information.